Acoustic Louvres - WLA Series

|

|

Features Features

|

- The use of acoustic louvres or control of plant noise to atmosphere is now a widely accepted practice.

- AMS developed a compact louvre, which ensures weather protection with significant acoustic performance and pleasing visual aspect.

- AMS acoustic louvres are supplied in galvanised or aluminium finishes.

- Plastic coatings, anodised aluminium or special paint finishes are available on request.

- Common applications for acoustic louvres are plant room air intakes and exhausts, cooling towers, refrigeration equipment, diesel generators, air cooled condensers and screen wall applications.

- To compliment the WLA acoustic louvres series AMS can provide matching profile standard weather louvres, these being designed type WL or for blanked off sections type WLD.

- All being available in the same finish options as for the WLA type acoustic louvres.

|

Acoustic Performance Acoustic Performance

|

- The acoustic performance table for WLA acoustic louvres is presented as a sound reduction index (transmission loss).

- In most practical applications the figures shown can be considered in the same way as the static insertion loss for an attenuator.

|

Construction Construction

|

- Louvre blade elements are manufactured from min.0.9 mm high quality galvanised sheet steel for the upper weather surface, acoustic infill being 47.5 kg/m density lass fibre with bonded surface membrane, retained by louvre blade under surface of steel wire mesh.

- The louvre blade elements are mounted in a 1.6 mm galvanised sheet steel peripheral channel framework with returned edges for unit strength and rigidity.

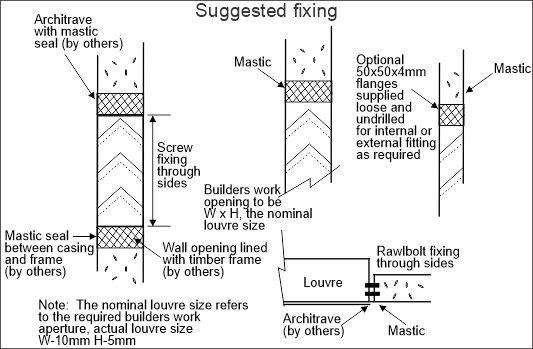

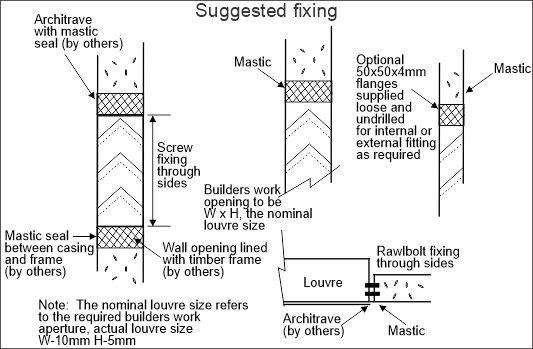

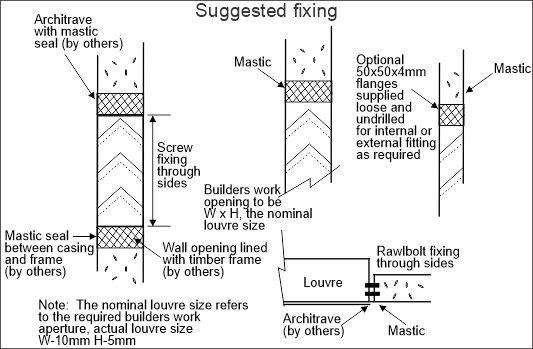

- Louvre additional options are bird mesh wire, internal or external flange frame, multi-section construction or architrave strip.

|

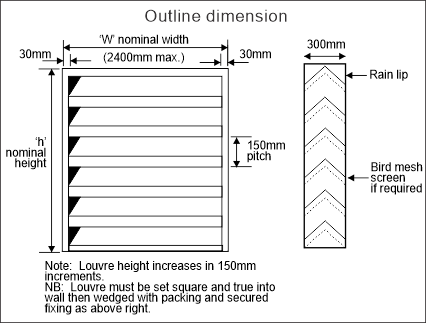

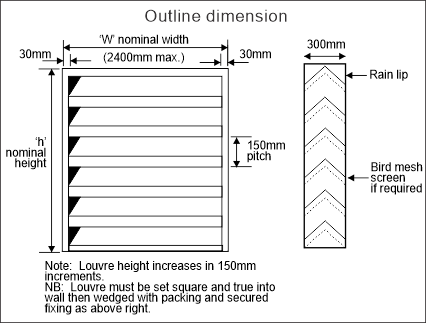

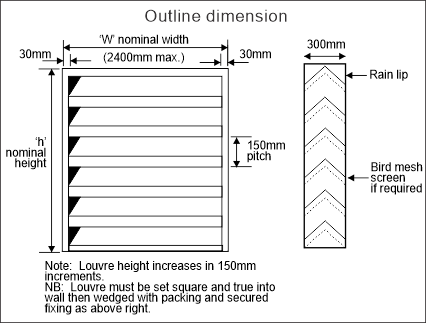

Dimensions Dimensions

|

|

| |

| Height |

Width,mm |

| mm |

600 |

750 |

900 |

1050 |

1200 |

1350 |

1500 |

1650 |

1800 |

1950 |

2100 |

2250 |

2400 |

| 600 |

18 |

23 |

28 |

31 |

37 |

43 |

48 |

55 |

59 |

68 |

83 |

96 |

107 |

| 750 |

23 |

31 |

37 |

44 |

52 |

57 |

64 |

75 |

82 |

92 |

104 |

116 |

128 |

| 900 |

30 |

38 |

45 |

53 |

63 |

69 |

79 |

87 |

95 |

108 |

118 |

126 |

140 |

| 1050 |

37 |

45 |

52 |

61 |

68 |

77 |

85 |

97 |

106 |

116 |

129 |

143 |

150 |

| 1200 |

43 |

52 |

60 |

67 |

75 |

85 |

94 |

107 |

113 |

130 |

145 |

150 |

157 |

| 1350 |

49 |

60 |

66 |

74 |

83 |

93 |

104 |

110 |

130 |

148 |

153 |

159 |

174 |

| 1500 |

60 |

66 |

75 |

81 |

94 |

102 |

110 |

133 |

146 |

152 |

160 |

175 |

181 |

| 1650 |

65 |

75 |

81 |

94 |

100 |

109 |

131 |

144 |

151 |

159 |

175 |

188 |

206 |

| 1800 |

70 |

81 |

92 |

101 |

108 |

129 |

143 |

150 |

156 |

178 |

191 |

208 |

228 |

| 1950 |

78 |

92 |

103 |

110 |

128 |

145 |

157 |

164 |

180 |

199 |

208 |

224 |

241 |

| 2100 |

86 |

103 |

111 |

130 |

140 |

153 |

161 |

174 |

190 |

209 |

225 |

240 |

258 |

| 2250 |

94 |

110 |

126 |

140 |

149 |

157 |

169 |

188 |

205 |

222 |

239 |

258 |

274 |

| 2400 |

101 |

124 |

137 |

148 |

156 |

166 |

184 |

200 |

219 |

236 |

252 |

269 |

286 |

|

| |

|

Sound Data Sound Data

|

| Acoustic Performance as tested by CSIR |

| |

Static Insertion Loss, dB |

| |

Octave Band Centre Frequency (Hz) |

| Model |

63 |

125 |

250 |

500 |

1k |

2k |

4k |

8k |

| WLA |

-5 |

-5 |

-7 |

-11 |

-17 |

-20 |

-16 |

-14 |

|

| |

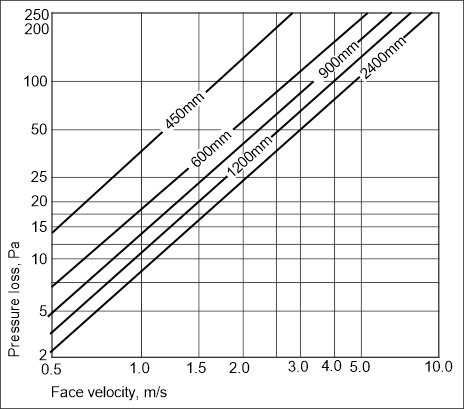

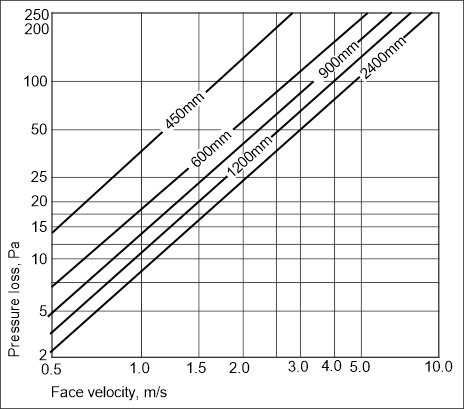

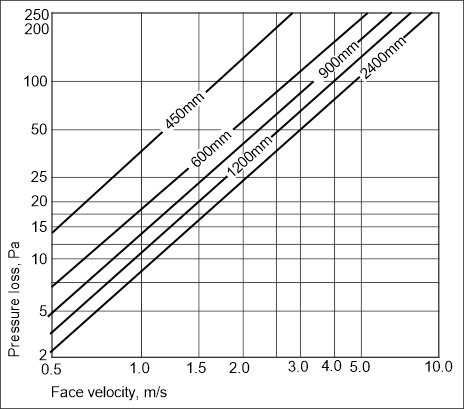

Pressure Drop Graph

|

|

PDF PDF

|